Products

Ceramic Coated Glass

IntroductionThe application of fused, colored ceramic paint to glass provides architects and designers with a new dimension in the use of patterned glass by offering a cost effective and unobtrusive means of minimizing exposure and controlling the amount of light transmission.

Colored ceramic paint used in the process of manufacture consists of glassflux (70-95%) and ceramic pigment (5-30%).

This type of patterned decorative glass is created by silk-screening the selected color and pattern onto one surface of the glass. Once the pattern has been applied, the glass is either toughened or heat strengthened with the heat generated within the furnace sufficient to melt the ceramic paint onto the glass.

Features:

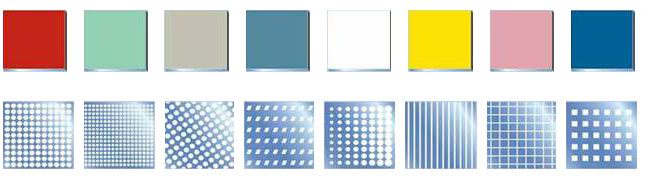

Various Color And Graphic Choices: Ceramic Coated Glass offers a variety of color and graphics that can be custom-made to meet designing needs.

Anti- Glare: The partial printing of silkscreen glass reduces glare.

Safety: Ceramic Coated Glass is tempered to improve safety.

Durable, Scratch-Proof And Moisture Resistance: Ceramic Coated Glass has higher durability, scratch-proof, moisture-resistant than ordinary color printed glass.

Areas Of Usage:

Architectural External Wall

Graphic Glass For Interior Partitions

Furniture And Art Glass

Thickness :2mm-25mm

Max size:2440mmx3660mm

Images:

|

|

|

|

Ceramic frit panels displayed along Orchard Road

|

||

|

|

Metrolite™ Ceramic Coated Colors & Patterns For Reference |