Heat Strengthened Glass

Tempered Glass With Heat Soak Test

Tempered Glass

Introduction

|

|

|

|

Tempered Glass uses the thermal process to enhance the basic strength of float glass. Here Glass panels are fed from the loading conveyer into the furnace where it oscillates back and forth on the ceramic rollers until it reaches a temperature of approximately 620 degree Celsius. When the glass panels come out of the furnace, it moves into the quencher where it is rapidly cooled by blasting both sides with cool air.

The rapid cooling induces compressive stresses to the glass surface. While the centre remains in tension. Although the physical characteristics remain unchanged, additional stress created within it increase the strength by 4-5 times that of float glass of equal thickness. This is known as Tempered Glass.

Features:

Strength: A fully tempered glass as required in ASTM C 1048 is generally 4 to 5 times stronger than annealed glass of similar thickness, size and type.

Temperature resistance: It withstands abrupt change of temperature difference of 170oC without breakage.

Spontaneous breakage: Due to nickel sulfide inclusion, spontaneous breakage is a characteristic of tempered glass.

Points To Note (Applicable For Both Tempered & Heat Strengthened)

Heat treated glass cannot be cut, drilled or chamfered after treatment; otherwise it will shatter into pieces.

Holes, notches and edge work have to be confirmed before tempering.

Tempered glass may break if deep cuts by impact are applied. If it does not shatter on impact, it occasionally shatters after a lapse of time.

Areas Of Usage:

Windows

Shop front

Structural glass

Shower screens

Bathtub enclosures

Escalator side panels

Sliding or swing doors

Furniture and interior decoration

Showcases

Partitions

Balustrades

Glass tables

Floors

Wall claddings

Images:

|

|

|

Shower screen

|

|

|

|

|

|

|

|

Glass Showcase |

Shop front |

Safety: Should accidental breakage occur; the resulting fragments are small and granular, causing minimal injury.

|

|

|

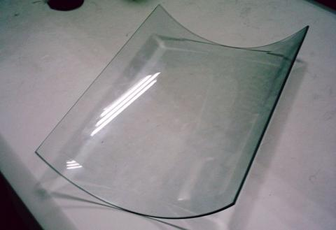

| Breakage Pattern Of Tempered Glass | Curved Tempered Glass |

Heat Strengthened Glass

Heat Strengthened GlassIntroduction

|

|

|

Heat Strengthened Glass which is widely used in the construction industry differs from tempered glass by its properties and its manufacturing process. When the glass panels are quenched at a slower rate. Result is lower compressive stress, increasing the strength to only twice that of float glass of equal thickness. This is known as Heat Strengthened Glass.

Features:

Strength: A fully tempered glass as required in ASTM C 1048 is generally 2 to 3 times stronger than annealed glass of similar thickness, size and type.

Temperature resistance: can withstand temperatures of up to 295 degree. It also provides resistance to thermal stress associated with high performance glazing materials such as tinted glass, reflective glass and Low-E glass in insulating units and spandrels.

Low Distortion: Lower processing temperature that results in faade having less optical distortion.

Low Risk Of Spontaneous Breakage: When broken by impact, heat strengthened glass breaks nearly the same way as annealed glass. It breaks into large pieces and remains in the window frames.

|

|

|

| Breakage Pattern Of Heat Strengthened Glass |

High-rise buildings

Commercial complexes

Residential buildings

Building facades

Insulating glass units

Spandrel glass

Windows

Link Glass: has its very own tempering line in China to supply local & International orders.

|

|

Spontaneous breakage is an inherent characteristic of tempered glass due to volume changes occurring during crystal form transformation of nickel sulfide inclusions and other defects present in the glass. Heat soak test is an effective way for bringing about spontaneous breakage before tempered glass panels are installed thus reducing risks of breakages after installation. By placing tempered glass in the heat-soak furnace, heating to a desired temperature, preserving for enough time and cooling down, the crystal form of nickel sulfide inclusions is stabilized and the internal stress is relaxed to a certain extent. During this process, tempered glass with large enough nickel sulfide inclusions and other defects will be broken by induced extra stresses. As a result, heat-soak treated tempered glass will have a much less chance of spontaneous breakage than normal tempered glass.

Link Glass has its own Heat- Soak Oven designed to reduce the risk of spontaneous breakage from Nickel Sulfide (Nis) inclusions. The process used is in compliance with the German DIN standards. While heat-soaking does not guarantee that breakage will be completely eliminated in the installed tempered glass; it is an invaluable test for identifying batches that have a high incidence of nickel sulphide inclusions.

Thickness :2mm-25mm

Max size:2440mmx3660mm